Adhesive joining of structural components has evolved significantly, offering innovative solutions for modern engineering challenges․ Recent advancements in materials and technologies provide enhanced strength and durability, enabling widespread applications across industries․ This method ensures efficient bonding while maintaining structural integrity, making it a critical area of research and development․ The book Adhesive Joining of Structural Components: New Insights and Technologies explores these developments, highlighting their potential to revolutionize manufacturing and construction processes․

1․1 Historical Overview of Adhesive Joining

Adhesive joining has its roots in ancient civilizations, where natural substances like plant resins and animal products were used to bond materials․ Over centuries, the technique evolved, with significant advancements during the Industrial Revolution․ The development of synthetic adhesives in the 20th century marked a turning point, enabling stronger and more durable bonds․ World War II accelerated research, leading to modern epoxy and acrylic adhesives․ The 1970s and 1980s saw the rise of structural adhesives for aerospace and automotive industries; Today, adhesive joining is a cornerstone of modern engineering, offering lightweight and corrosion-resistant solutions․ Its historical progression underscores its critical role in advancing material science and manufacturing․

1․2 Importance of Adhesive Joining in Modern Engineering

Adhesive joining is indispensable in modern engineering due to its ability to create lightweight, high-strength, and corrosion-resistant structures․ Unlike traditional methods, adhesives enable bonding of dissimilar materials, crucial for industries like aerospace and automotive; They distribute stress uniformly, reducing fatigue and improving durability․ This technique minimizes weight, enhancing fuel efficiency in vehicles and aircraft․ Additionally, adhesives provide smooth, sealed surfaces, reducing drag and improving aerodynamics․ Their versatility and performance make them essential for complex, cutting-edge designs, driving innovation and efficiency across sectors․ As industries seek sustainable solutions, adhesive joining continues to be a key enabler of advanced manufacturing and structural integrity․

Recent Advances in Adhesive Joining Technologies

Recent advancements include functional interlocking metasurfaces, adhesive-free joining, and localized spot joints, enhancing structural strength, efficiency, and suitability for large components and advanced manufacturing processes․

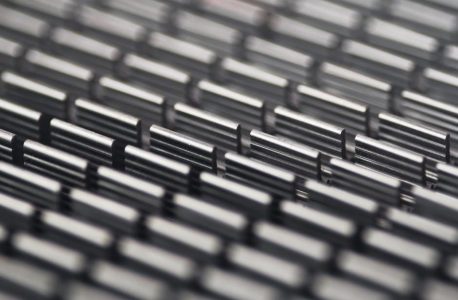

2․1 Functional Interlocking Metasurfaces (ILMs)

Functional interlocking metasurfaces (ILMs) represent a groundbreaking innovation in adhesive joining, offering superior structural strength and stability․ Developed by engineers at Texas A&M University, ILMs replace traditional nuts, bolts, and adhesives with intricate surface patterns that interlock to distribute loads more effectively․ This technology not only enhances mechanical performance but also reduces weight, making it ideal for applications in aerospace and automotive industries․ ILMs provide a scalable solution for joining large and complex components, ensuring precision and durability without the need for conventional fastening methods․ Their implementation promises to revolutionize manufacturing processes, enabling the creation of stronger, lighter, and more efficient structures․ This advancement underscores the potential of metasurfaces in next-generation engineering․

2․2 Adhesive-Free Joining and Additive Manufacturing

Adhesive-free joining combined with additive manufacturing offers a novel approach to bonding structural components without traditional adhesives․ Researchers at Graz University of Technology developed this innovative process, enabling direct integration of materials during manufacturing․ This method eliminates the need for adhesives, reducing weight and potential failure points․ It is particularly suitable for large components and 2D structures, achieving precise localized spot joints․ By streamlining production, this technology enhances efficiency and opens new possibilities for complex geometries․ The elimination of adhesives also simplifies recycling and reduces environmental impact․ This breakthrough is poised to transform industries requiring high-performance, lightweight structures, such as aerospace and automotive, by providing a durable and sustainable alternative to conventional bonding techniques․

2․3 Localized Spot Joints for Large Components

Localized spot joints represent a significant advancement in bonding large structural components․ This method achieves precise, high-strength bonds at specific points, eliminating the need for extensive adhesive coverage․ It is particularly effective for large-scale structures, where traditional bonding methods may fail due to stress concentrations or material limitations․ Researchers like Awais Awan have demonstrated the suitability of localized spot joints for 2D structures, ensuring optimal load distribution and minimal material waste․ This technique not only enhances structural integrity but also reduces production costs and environmental impact․ Its application in industries like aerospace and automotive is growing, offering a reliable alternative to conventional bonding techniques for oversized components․

Bonding Technologies and Surface Preparation

Advanced bonding technologies and surface preparation methods are critical for ensuring strong, durable joints․ Proper surface treatment enhances adhesion, while innovative bonding techniques optimize material compatibility and structural performance․

3․1 Advanced Surface Preparation Methods

Advanced surface preparation methods are essential for ensuring optimal adhesion and durability in adhesive joining․ Recent innovations include techniques like laser cleaning, plasma treatment, and nanomaterial coatings, which enhance surface roughness and chemical compatibility․ These methods minimize contaminants and create a stable interface for bonding․ Engineers at Texas A&M University have also developed functional interlocking metasurfaces (ILMs), which improve structural strength without requiring traditional adhesives․ Additionally, researchers focus on environmentally friendly processes, such as solvent-free treatments, to reduce environmental impact while maintaining performance․ These advancements ensure stronger, more reliable bonds, critical for applications in aerospace, automotive, and industrial sectors․

3․2 Emerging Adhesive Materials and Their Properties

Emerging adhesive materials are revolutionizing the field of structural component bonding․ Bio-inspired adhesives, nanomaterials, and stimuli-responsive polymers are gaining traction for their unique properties․ These materials offer enhanced strength, flexibility, and resistance to environmental factors like temperature and humidity․ For instance, nanomaterial-based adhesives exhibit superior mechanical properties and durability, making them ideal for high-performance applications․ Additionally, researchers are developing eco-friendly adhesives with reduced volatile organic compounds (VOCs) and improved sustainability․ These advancements ensure better compatibility with modern materials like composites and lightweight alloys, addressing critical challenges in industries such as aerospace and automotive manufacturing․ Their integration into manufacturing processes promises to enhance the reliability and longevity of bonded structures․

Industry-Specific Applications of Adhesive Joining

Adhesive joining is widely applied across aerospace, automotive, and construction industries, enabling lightweight, durable, and corrosion-resistant structures․ Its versatility addresses specific challenges in each sector, enhancing performance and efficiency․

4․1 Adhesive Joining in Aerospace Engineering

In aerospace engineering, adhesive joining plays a crucial role in constructing lightweight, high-performance aircraft and spacecraft components․ Advanced adhesives enable the bonding of dissimilar materials, such as composites and metals, which is essential for modern aerospace structures․ These bonds must withstand extreme temperatures, vibrations, and stress, making durability and reliability paramount․ The use of functional interlocking metasurfaces (ILMs) has further enhanced structural integrity, providing alternatives to traditional fastening methods․ This innovation not only reduces weight but also improves fuel efficiency and overall aircraft performance․ As a result, adhesive joining is indispensable in advancing aerospace technology and meeting the industry’s stringent requirements․

4․2 Adhesive Joining in Automotive Manufacturing

Adhesive joining is a cornerstone of modern automotive manufacturing, enabling the production of lightweight, durable, and energy-efficient vehicles․ Advanced adhesives are used to bond materials like steel, aluminum, and carbon fiber, reducing weight while maintaining structural integrity․ This is critical for electric vehicles (EVs) and hybrid models, where weight reduction directly impacts battery life and performance․ Additionally, adhesive joining enhances safety by creating strong, crash-resistant bonds․ The automotive industry has also embraced adhesive-free joining techniques, particularly in combination with additive manufacturing, to create complex components without the need for traditional adhesives․ These innovations are driving the sector toward more sustainable and efficient manufacturing processes, aligning with global environmental goals․

Challenges and Limitations of Adhesive Joining

Adhesive joining faces challenges like durability, surface preparation, and material incompatibility, impacting long-term performance and reliability in harsh environments, requiring advanced solutions for optimal results․

5․1 Durability and Long-Term Performance

Durability and long-term performance remain critical challenges in adhesive joining․ Environmental factors like temperature, humidity, and exposure to chemicals can degrade bond strength over time․ Additionally, cyclic loading and stress can lead to fatigue, compromising the structural integrity of joints․ Ensuring consistent and reliable long-term adhesion requires precise surface preparation and the use of high-performance adhesives․ Recent advancements in materials science have introduced new adhesive formulations with improved resistance to environmental degradation, addressing these concerns․ However, further research is needed to fully understand and mitigate the effects of aging and stress on bonded structures, ensuring their longevity in industrial applications․

5․2 Stress and Load Distribution in Bonded Joints

Stress and load distribution in bonded joints are critical factors influencing their performance․ Uneven stress distribution can lead to premature failure, especially under dynamic or cyclic loading conditions․ The design of the joint and the properties of the adhesive significantly impact how loads are transferred across the interface․ Advanced finite element modeling techniques are now used to predict stress concentrations and optimize joint design․ Additionally, innovations like functional interlocking metasurfaces (ILMs) and hybrid adhesives help distribute loads more evenly, enhancing overall joint reliability․ Proper surface preparation and material selection are also vital to ensure uniform stress distribution, minimizing the risk of localized failures․ These advancements aim to maximize the structural integrity of bonded components under various operational conditions․

Non-Destructive Testing of Adhesive Joints

Non-destructive testing of adhesive joints ensures bond quality and structural integrity․ Advances in ultrasonic testing and acoustic emission improve defect detection, enhancing reliability and safety in critical applications․

6․1 Advances in NDT Methods for Bonded Structures

Recent advancements in non-destructive testing (NDT) methods have significantly improved the evaluation of adhesive joints․ Techniques such as ultrasonic testing, acoustic emission, and infrared thermography now offer enhanced accuracy in detecting defects, voids, and weak bonds․ These methods enable real-time monitoring of bond quality without damaging the structure․ Innovations in automated scanning systems and advanced signal processing algorithms further boost reliability․ Such progress is crucial for ensuring the integrity of bonded components in critical applications, such as aerospace and automotive industries, where failure can have severe consequences․ These cutting-edge NDT tools are highlighted in the book as essential for modern engineering practices․

Environmental and Sustainability Considerations

The development of eco-friendly adhesives and sustainable bonding processes is a growing focus, emphasizing reduced environmental impact and aligning with global sustainability goals․

7․1 Eco-Friendly Adhesives and Processes

Recent advancements in adhesive joining emphasize the development of eco-friendly materials and sustainable processes․ Researchers are focusing on bio-based adhesives derived from renewable resources, which reduce reliance on petroleum-based products․ These green adhesives not only minimize environmental impact but also offer comparable or superior performance to traditional alternatives․ Additionally, innovative manufacturing techniques are being implemented to lower energy consumption and reduce waste during production․ Such sustainable practices align with global efforts to reduce carbon footprints and promote environmentally responsible engineering solutions․ The adoption of these eco-friendly adhesives and processes is expected to play a pivotal role in the future of adhesive joining technologies․

Future Trends and Innovations

Emerging technologies, such as smart materials and predictive maintenance systems, are reshaping adhesive joining․ These innovations enhance durability, efficiency, and adaptability in various engineering applications․

8․1 Integration of Smart Materials and Sensors

The integration of smart materials and sensors into adhesive joining systems represents a groundbreaking advancement․ These materials can adapt to environmental changes, enhancing the durability and adaptability of bonded structures․ Sensors embedded within adhesives enable real-time monitoring of stress, temperature, and potential failures, allowing for predictive maintenance․ This technology not only improves reliability but also reduces maintenance costs․ Researchers are exploring self-healing adhesives that can repair minor damages autonomously, further extending the lifespan of structural components․ Such innovations are particularly valuable in aerospace and automotive industries, where safety and performance are paramount․ This integration of intelligence and adaptability is poised to redefine the future of adhesive joining technologies․

8․2 Predictive Maintenance and Monitoring Systems

Predictive maintenance and monitoring systems are revolutionizing the management of adhesive joints in structural components․ By leveraging advanced sensors and machine learning algorithms, these systems enable real-time monitoring of joint integrity, detecting early signs of degradation or failure․ This proactive approach minimizes unplanned downtime and extends the lifespan of critical structures․ Engineers are integrating these systems with smart materials to create adaptive bonds that respond to environmental changes․ Such innovations are particularly beneficial in industries like aerospace and automotive, where safety and reliability are paramount․ Predictive maintenance not only enhances operational efficiency but also reduces long-term costs, making it a cornerstone of modern adhesive joining technologies․